Understanding the Basics of Membrane Bioreactor Systems for Wastewater Management

Understanding the Basics of Membrane Bioreactor Systems for Wastewater Management

Blog Article

Comprehending Membrane Bioreactors: The Future of Wastewater Therapy

Membrane bioreactors (MBRs) stand for a significant development in the area of wastewater therapy, integrating organic procedures with advanced membrane layer purification to boost effluent quality. As worldwide water shortage and rigorous regulative structures end up being increasingly pushing issues, MBR modern technology offers a reliable action through its ability to reduce impact and enhance source recovery.

What Are Membrane Layer Bioreactors?

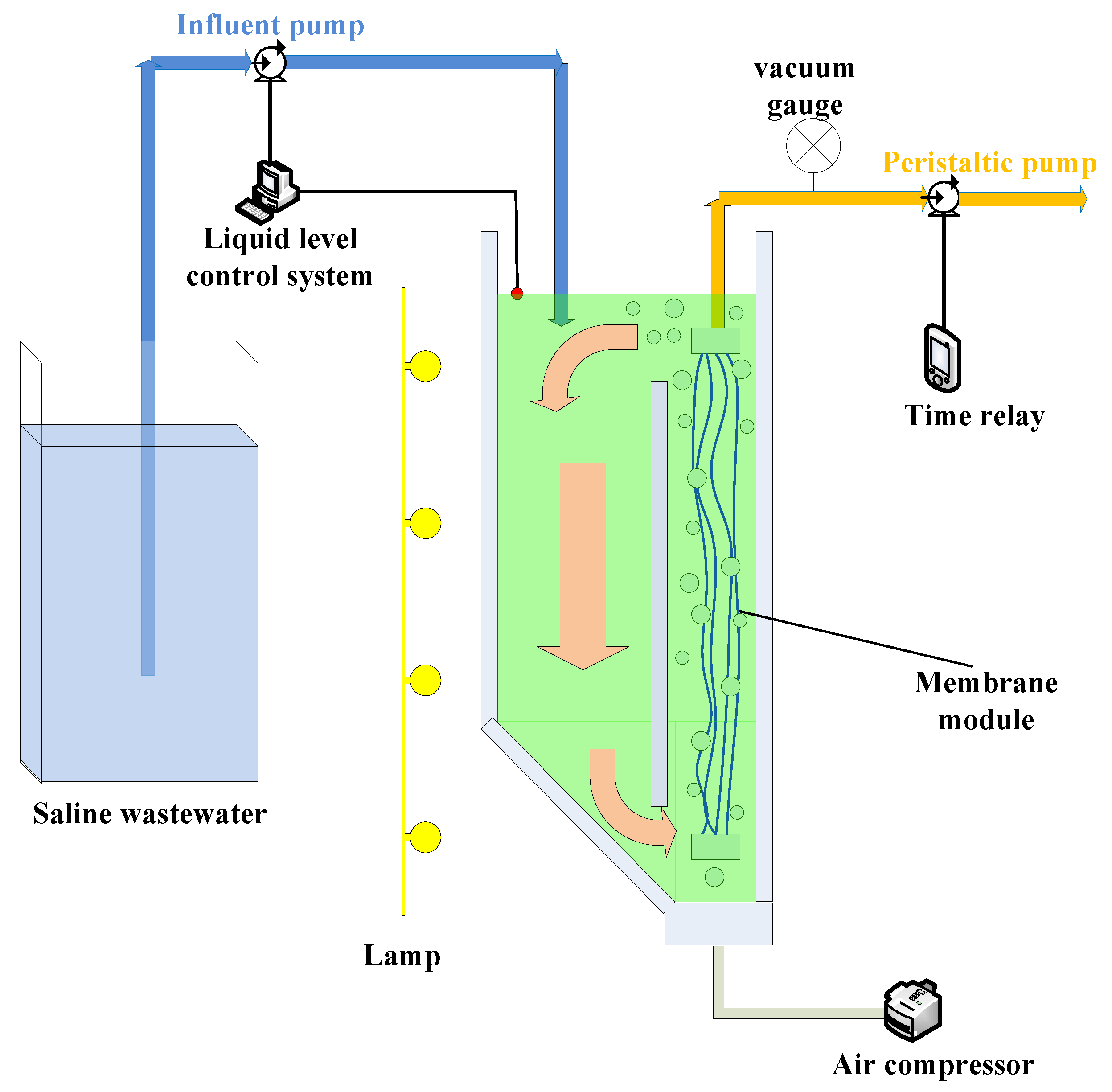

The core components of MBR systems consist of a bioreactor where microbial task takes place and a membrane device that filters the blended alcohol. This twin functionality enables the simultaneous deterioration of raw material and solid-liquid splitting up in a single step. MBRs can run in both immersed and outside arrangements, with immersed systems being much more typical due to their small layout and operational performance.

The fostering of MBR technology has gained grip in different applications, varying from community wastewater treatment to commercial effluent management. MBRs are particularly advantageous in circumstances where space is minimal or rigid effluent top quality requirements should be met. By maintaining a high concentration of microorganisms within the bioreactor, MBRs boost the degradation of organic pollutants, therefore yielding greater therapy efficiencies contrasted to traditional techniques.

Trick Advantages of MBR Modern Technology

The combination of biological treatment with membrane layer filtering in MBR systems provides countless benefits that set it besides conventional wastewater treatment techniques. One of the primary advantages is the improved effluent high quality. MBRs successfully remove suspended solids and pathogens, accomplishing higher degrees of filtration that satisfy stringent discharge criteria and facilitate water reuse applications.

An additional significant advantage is the lowered sludge production. MBR systems generate less excess sludge, bring about lower disposal expenses and a reduction in environmental influence. The closed nature of the membrane system minimizes the risk of odor discharges and enhances general procedure control.

Finally, MBRs are adaptable and flexible, making them suitable for various wastewater kinds, including industrial and metropolitan sources. The capability to integrate with advanced treatment innovations further enhances their effectiveness, making MBRs a promising remedy for the future of wastewater administration.

Challenges and Limitations of MBRs

While MBR technology supplies many benefits, it likewise encounters several challenges and restrictions that can influence its prevalent fostering. One substantial challenge is the high resources and functional expenses linked with MBR systems. The preliminary investment for membrane layer materials and the essential framework can be significant, making it less easily accessible for smaller sized sectors or districts.

In addition, membrane fouling continues to be an essential concern that can reduce system performance and rise maintenance demands. Fouling takes place when solids, raw material, or microorganisms accumulate on the membrane surface area, resulting in decreased permeability and requiring frequent cleaning or substitute.

An additional limitation involves the intricacy of the technology. MBR systems call for experienced personnel for operation and upkeep, which can be a barrier in regions with limited technical proficiency. Furthermore, the disposal of invested membrane layers provides ecological issues, as the materials are commonly not naturally degradable and can add to squander monitoring obstacles.

Finally, while MBRs can efficiently treat a wide variety of wastewater, they might not be suitable for all applications, especially those with high concentrations of fats, oils, and greases, requiring further research study and advancement to deal with these constraints.

Applications of Membrane Bioreactors

In different sectors, membrane layer bioreactors (MBRs) have actually emerged as a functional service for wastewater treatment (Membrane Bioreactor). Their applications span community, industrial, and farming settings, showcasing their flexibility and efficiency in hop over to here diverse settings. In municipal wastewater treatment plants, MBRs significantly improve effluent quality, enabling water reuse and decreasing the ecological influence of discharged wastewater

Industrially, MBRs are utilized in food and drink processing, fabric manufacturing, and pharmaceutical production, where they properly treat high-strength waste streams. Their capacity to deal with fluctuating tons and varying impurity concentrations makes them specifically valuable in these industries. In addition, MBRs facilitate the elimination of virus, put on hold solids, and organic issue, adding to compliance with stringent discharge laws.

In agriculture, MBRs are progressively made use of for treating farming drainage and livestock wastewater, making it possible for the healing of nutrients for fertilizer production. They also aid in the treatment of greywater for watering, promoting lasting water management practices.

The versatility of MBRs is additional shown by their integration with various other modern technologies, such as anaerobic food digestion and progressed oxidation procedures, improving general efficiency and source healing in wastewater therapy systems.

The Future of Wastewater Treatment

Advancements in modern technology and a growing emphasis on sustainability are forming the future of wastewater therapy. Membrane bioreactors (MBRs) exhibit this shift by integrating organic therapy procedures with membrane layer filtration, leading to premium effluent find here ideal for reuse. The pattern towards round economic climates is motivating facilities to embrace MBRs for their capacity to recuperate sources, such as water useful site and nutrients, from wastewater.

Technologies in membrane layer materials and setup are boosting the effectiveness and longevity of MBR systems, reducing operational expenses and power consumption. Smart technology assimilation, consisting of real-time surveillance and automated control systems, is more enhancing performance and allowing anticipating upkeep, hence minimizing downtime.

Furthermore, regulative stress and societal expectations are pushing municipalities and industries to adopt even more lasting practices. Membrane Bioreactor. The change in the direction of decentralized wastewater therapy solutions is acquiring traction, permitting localized treatment that lowers transportation expenses and power use

Final Thought

Membrane bioreactors (MBRs) represent a transformative technique to wastewater therapy, incorporating biological procedures with sophisticated membrane technology. The benefits of MBRs, including improved effluent quality, lowered spatial requirements, and lower sludge manufacturing, place them as a feasible option in the middle of growing urbanization and more stringent ecological laws. Regardless of existing difficulties, the continued technology in membrane materials and operational approaches promises to boost the effectiveness and fostering of MBRs, ensuring their pivotal function in the future of sustainable wastewater management.

Membrane bioreactors (MBRs) stand for a significant innovation in the field of wastewater treatment, integrating organic procedures with advanced membrane purification to enhance effluent top quality.Membrane bioreactors (MBRs) combine biological treatment procedures with membrane filtering to properly deal with wastewater.The assimilation of organic treatment with membrane filtering in MBR systems provides various benefits that establish it apart from standard wastewater treatment approaches. Membrane layer bioreactors (MBRs) exhibit this change by integrating biological treatment processes with membrane purification, resulting in high-quality effluent suitable for reuse.Membrane bioreactors (MBRs) stand for a transformative technique to wastewater treatment, incorporating organic processes with innovative membrane technology.

Report this page